Applicable shaft and pipe parts; Number of stations, optional configuration; Auxiliary supporting and limiting deformation mechanism of parts; Stepped loading and unloading mechanism;

Applicable shaft and pipe parts; Number of stations, optional configuration; Auxiliary supporting and limiting deformation mechanism of parts; Stepped loading and unloading mechanism;

Adopt software programming, use the memory function of the system to dynamically monitor the output voltage, current and power of the heating power supply, and set and display the flow rate (set value and actual value), pressure, temperature (set value and actual value) and liquid level of cooling water and hardening liquid. The system compares the real-time heating data with the sample data, when the tolerance range of the set template data is exceeded, the alarm will be given, and the defective workpiece can be isolated accordingly, thus avoiding the defective product from flowing out of the production line;

Specializing in coil manufacturing for more than 20 years, with an annual output of over 1,000 units and rich experience; Our products are not only suitable for domestic machine, but also provide consulting and supporting services for imported equipment; Fully equipped, all coils are strictly tested and tested before leaving the factory; We have a skilled team, anytime and anywhere to provide on the coil manufacturing, testing, repair and other services;

According to the individual needs of customers, a reasonable and feasible scheme is given, and the induction hardening machine is designed and produced to meet its requirements. For example, die hardening machines, automobile stabilizer bar forming and hardening machines.

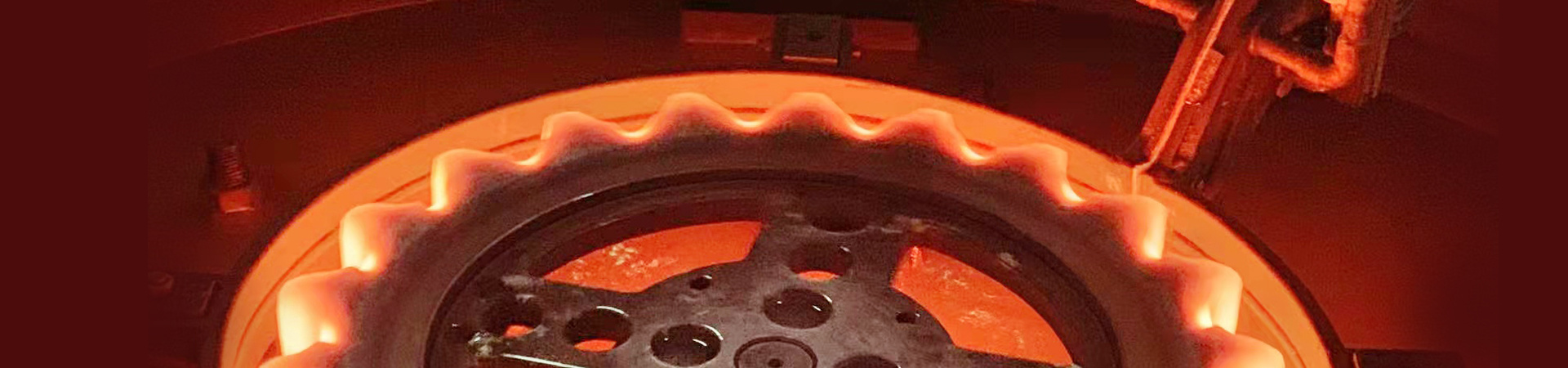

Induction forging heating is widely used in the metal and casting and forging industries to heat billets, bars and bar ends. The forging heating equipment we provide includes hopper loading, visual loading, temperature three... and other functions.

Induction melting is a process in which a metal is melted into a liquid state in a crucible in an induction furnace. The molten metal is then poured from the crucible into the mold. Induction heating for melting has the characteristics of high efficiency, good controllability, automation and safe operation.

Brazing is a material joining process that uses a brazing material and an oxidation resistant solvent, commonly known as a flux, to join two pieces of metal together without melting the base material. Induction brazing has many advantages: fast heating speed, improved production efficiency, green environmental protection, safety, can work in vacuum or gas protection environment, easy to realize automation, etc.

Induction curing bonding techniques use induction heating to cure the bonding adhesive. It is the main method of curing adhesives and sealants for automotive parts. It can also cure adhesives in composite materials and metal and carbon fiber and carbon fiber joints.

WhatsApp/Mobile: +86 18772998821

E-mail: marketing@ts-heating.com

Address: Building 1, No.41, Xicheng Road, Xicheng Development Zone, Zhangwan District, Shiyan City, Hubei Province