Transmission shaft automatic hardening production line

No PLC, full FPGA control, completely avoid the damage caused by the environment and time of the chip, with high processing speed, to ensure the efficient and orderly operation of the device, with real-time computing power and real-time simulation and simulation capabilities, device reliability is extremely high. Compared with regular processors, the accuracy of control and measurement is obviously improved, the speed and reliability of limitation and protection are enhanced, the functions of quantity processing and display operation are greatly increased, the phase-controlled digital trigger circuit is reliable, the symmetry of pulse generation is good, the function of the whole three-phase trigger is integrated on a programmable logic device, the hardware and software are very saved, the anti-interference ability is strong, and the volume of pulse transformer and the burden of output power amplifier tube are reduced, it also has three-phase AC phase sequence adaptive, three-phase AC phase loss automatic protection and other functions, constant voltage or constant power can be switched;

With the development of new energy vehicles and the development of automatic driving, the technology of steering gear is also undergoing rapid transformation. We have established heat and reliable application lines on C- EPS, P-EPS, DP-EPS and R-EPS steering gears. We have provided mature and reliable complete sets of equipment, which are also gaining the trust of more and more customers.

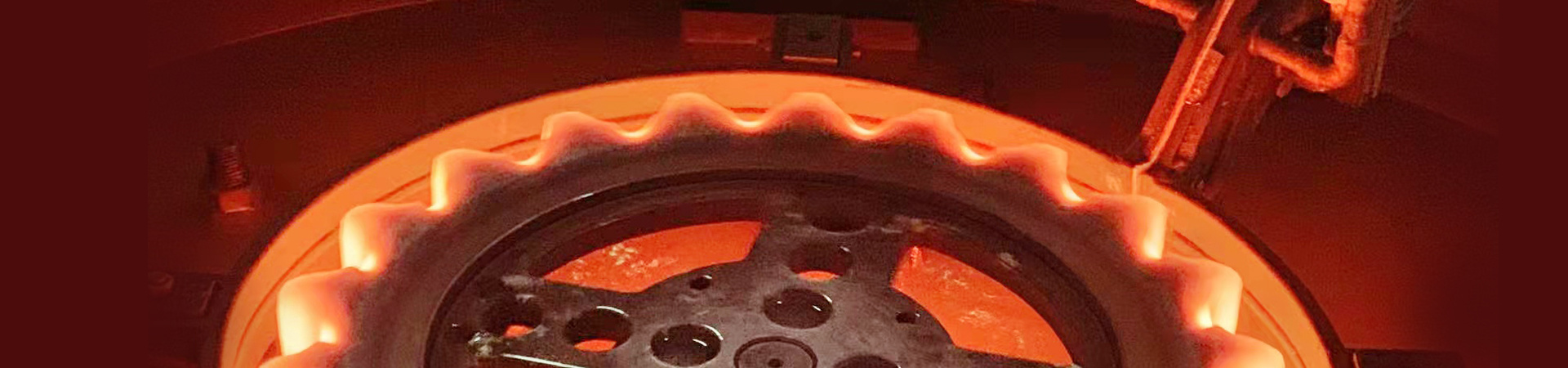

Hub shaft hardening machine, 3-axis (Z/Y/C) Inductor moving; Clamp 2 sets of 1000mm,200KW power supply;

Single position single axis, 2 servo axes (Y/Z); Inductor moving; Clamping 300mm,100KW power supply;

One clamping, complete the hardening of the tooth surface/tooth back;

Equipped with a process parameter monitoring system that is traceable, replicable, and has a power tolerance curve. The power curve of each component can be displayed and recorded; Each part operator information, workpiece information, fixture information, voltage, current, power, flow rate, temperature, etc. are all automatically recorded and can be connected to the internet;

Equipped with a process parameter monitoring system that is traceable, replicable, and has a power tolerance curve. The power curve of each component can be displayed and recorded; Each part operator information, workpiece information, fixture information, voltage, current, power, flow rate, temperature, etc. are all automatically recorded and can be connected to the internet;

With induction tempering function; Automatic loading and unloading;

WhatsApp/Mobile: +86 18772998821

E-mail: marketing@ts-heating.com

Address: Building 1, No.41, Xicheng Road, Xicheng Development Zone, Zhangwan District, Shiyan City, Hubei Province